I had the pleasure to talk on the last Procurement Summit in Hannover about Procurement and its place in agile Development Projects. Unfortunately it is only available in German ….

Category Archives: Target Costing

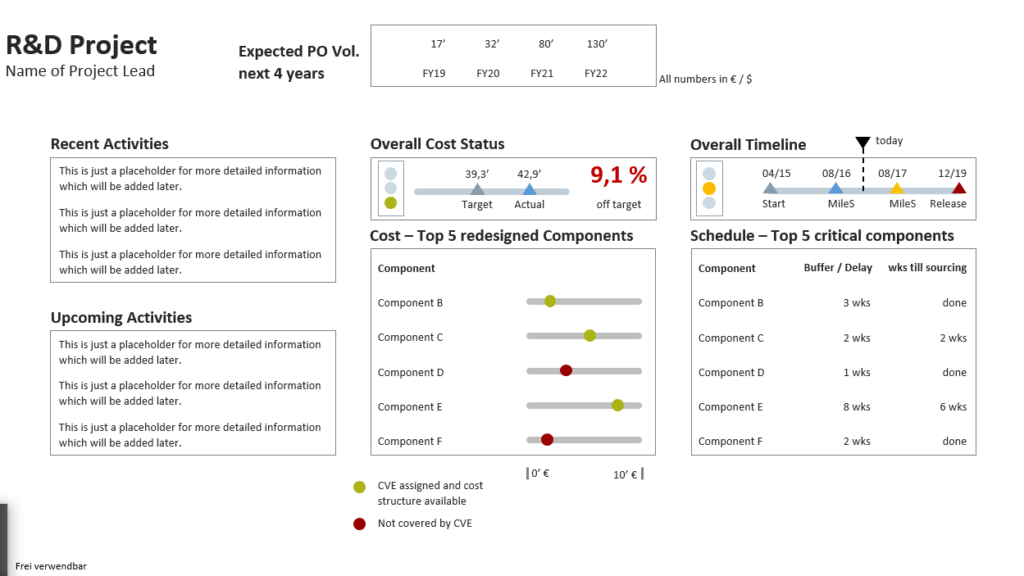

How to report the cost status of a R&D Project

The R&D Project cost and schedule status are the most important KPI’s for a procurement organization. Therefore, it is not surprising that the head of procurement or CPO focus his interest of these two areas. If you are the procurement representative in an R&D project, you should consider this. Many of you have faced already the balancing act to deliver the key message and not getting lost in all the details. I developed a PowerPoint template which addresses the expectations from senior management. This template was already used in many different reviews and is proven best practice.

Continue readingHow to use “Target pricing” and „Target costing” in procurement and what is the difference?

All of you already have experienced the difference between cost and price. Before and after the holiday weekend the fuel price is significantly different while the cost stayed the same. In procurement we deal with supplier prices every day, but is there any value for us to investigate the potential price of our product? The following article will elaborate on the difference of cost and price and how we need to use it in our daily procurement world.

Continue readingProduct Cost Management during an R&D Project – Part 1

Introduction to Product Cost Management

A company’s health and longevity are linked to how well it can sustain and grow its profits over time. From a simplified perspective, the company can achieve this longevity by (1) increasing its revenue, and/or (2) improving its profit margin. This six-part-series focuses on the later: improving profit margins via successful product cost management during an R&D project. The series includes the following sections:

- Set the Tone Early. Check Back with the Market Often.

- Create Transparency

- Communicate

- Teach & Empower

- Align Key Cost Decisions with Program Schedule

- Execute. And Document the Decision Logic.

The sections flow in chronological order, although it is important to know that many of these steps are only effective when they are sustained in parallel throughout the entire project timeline. This will become more clear as we progress through the sections together.

Continue readingHow to lever “Design to Customer Value” in your daily work

In one of my previous articles I introduced you to different methods or levers to maximize the outcome of your work. We call it “Design to Value”. The article on “Design to Cost” was the first one. I continue you now with an article on “Design for Customer Value”.

It is a little bit confusing that “Design to Customer Value” is a sub category of “Design to Value”, but you really have to highlight here the “Customer”. Essentially it is about to understand the real needs of the customer and how the product can generate value for our customer.

Continue readingAre alloy wheels totally overpriced?

Once in a live most of the car owners need to buy wheels for his car. The question is: Which price is reasonable for the product? Which kind of wheels to choose? In this article you will find answers on that question. Additionally, you get an overview about a cost structure of an aluminum casting product using bottom up cost calculation method. We think it’s a perfect example to show how cost value engineering contributes to the company’s success and could also help you in your private life.

Continue readingWhy to employ Cost Engineers while Procurement Engineers are available?

What is the difference between Procurement and Cost Engineers and is it worth to have both in the team setup? This will be very roughly discussed by using an example and providing a guideline when this might make sense for a company. As always there is no simple answer. Some facts might help to make the decision: size of company; size of commodity, complexity of commodity & skill set of procurement engineers. Fact is that both roles (should) have at least 50% overlap in their expertise.

Continue readingQuestions you should ask in a job interview with a potential Procurement Engineer

These questions have been extensively used in various interviews and helped us to identify whether the candidate was or is the right one. Beside the focus on Procurement Engineering I would always recommend preparing a list of questions you want to ask as a kind of checklist to ensure that you ask the different candidates the same. Make notes during the interview. So more details you have so better. At the end of the interview make a summary. After you had all the interviews, sit down and review all interviews with your written notes. This prevents that you automatically select one of the last candidates as they are more present in your memory. I added to every question some background information why you should ask exactly this question and what is the expectation.

Continue readingActive procurement role on driving big cost out projects

Supply chain management (SCM) has developed and changed so quickly to meet new business mode and market requirements today. Procurement as one of most important element in SCM is also undergoing significant change, which in sequence impacts its role and responsibility in whole organization. What’s new from procurement to bring bigger impact on business is really an interesting topic worth to understand and explore. This post to explain how procurement acts as a more active role and brings impact in one localization (cost out) project based on author’s experience. In here, Procurement engineer plays the interface/lead role from procurement organization.

Continue reading