Introduction to Product Cost Management

A company’s health and longevity are linked to how well it can sustain and grow its profits over time. From a simplified perspective, the company can achieve this longevity by (1) increasing its revenue, and/or (2) improving its profit margin. This six-part-series focuses on the later: improving profit margins via successful product cost management during an R&D project. The series includes the following sections:

- Set the Tone Early. Check Back with the Market Often.

- Create Transparency

- Communicate

- Teach & Empower

- Align Key Cost Decisions with Program Schedule

- Execute. And Document the Decision Logic.

The sections flow in chronological order, although it is important to know that many of these steps are only effective when they are sustained in parallel throughout the entire project timeline. This will become more clear as we progress through the sections together.

Set the Tone Early

So, you are kicking-off an R&D project to create a new product! Typical program targets/focus will include: schedule, R&D budget, and technical requirements coming from the customer(s). An equally important, but often undervalued, aspect of program target setting should also be the target cost of the product, itself. Leadership must set the tone for the program early (preferably from Day #1) that cost targets are at the same priority level as all other program targets mentioned above. If your new product development is already underway, don’t delay! It is better to set the cost-out focus late than not-at-all. If you don’t establish cost optimization as a program priority, it is common (especially in engineering-focused organizations) to hear the phrase,

“…we will design the best technical solution, and then we can figure out how to get cost-out afterwards…”

This is an antiquated view based on two key misconceptions that will be addressed in this article.

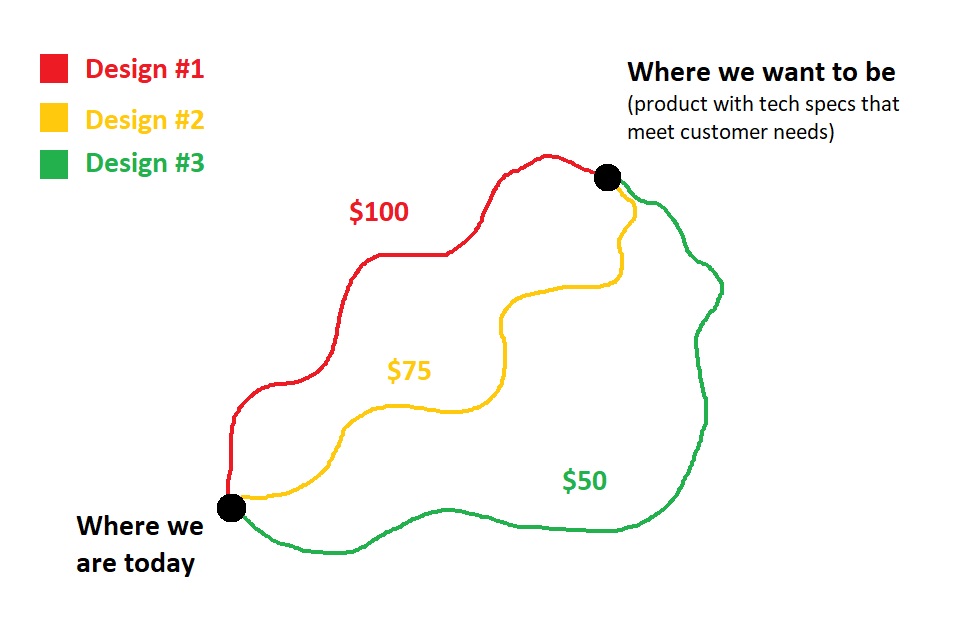

The first misconception is that you can have the best technical solution, or you can have a low-cost solution … but not both. This assumes that all cost-out comes at the detriment to quality and/or technical specifications of the product (life, function / performance, aesthetics / ergonomics). This statement can be true if you assume you have a fixed design and can only reduce cost by removing valuable features, downgrading materials at the detriment of life/aesthetics, etc. (ex. Design #1 made of steel vs. Design #1 made of iron vs. Design #1 made of plastic). However, if you consider cost optimization during concept development, you can potentially come up with multiple completely independent designs which each achieve all of the customer requirements at varying cost positions. This is what is known as “Design to Value.” The graphic below can help illustrate this idea:

In this scenario, we take three completely different design paths which have three completely different product costs, but all three concepts in the end arrive at a solution that meets all of the customer’s technical needs (life, function/performance, aesthetics/ergonomics, etc.). Without an early focus on cost-optimization the team may stop on Design #1 and believe that they have met all of their objectives but come to find out later that no one will buy their product because there are more affordable alternatives in the market.

The second misconception is that you can get the same amount of cost-out after-the-fact as you can from the beginning of development. Using the same example from above, the team without early cost-focus would say,

“…Ok, we have created Design #1, and it costs $100. Now let’s try to get the cost down.”

Working within the architectural constraints of Design #1, the team may find that over time they can optimize certain non-critical features that are driving costs up, optimize manufacturing processes, negotiate better raw material prices with suppliers, but they reach a plateau at $70. They may celebrate this as a success – after all, it is a 30% cost reduction! – but when compared to Design #2 it becomes clear that applying some of those same cost-out strategies would likely have driven the Design #2 even lower than $70 over the same time frame. Even more apparent is that Design #3 costs less today than the cost-optimized Design #1 of the future.

Check Back with the Market Often

Achieving profitability of the new product line isn’t guaranteed simply by establishing a product cost target, but your odds are greatly increased. Once the tone is set and product cost targets have been established, the program should check back with the market at a regularly defined interval throughout the development to ensure that the market price expectations are not changing drastically over time. This is especially important in product developments that stretch over many months or years.

There is no ‘one-size-fits-all’ solution for the frequency of this interval as it is highly dependent on the specific market you are in, but finding the right balance is critical. If you never change the product cost target (even after a major shift in market expectations occurs), you run the risk of rolling the product out into the market only to realize you have to go back to the drawing board – potentially undoing months of work and further delaying your ability to bring in revenue.

Alternatively, if you adjust your cost targets too often to reflect the latest whims of the market, it can create apathy within the design team towards cost. You will begin to hear grumblings of,

“…What is the point of trying to meet these cost targets? They are just going to change again next week, and all of our design decisions will need to be re-evaluated…”

This sentiment is counterproductive and can lead to decision-making akin to if there was no cost optimization focus at all (a.k.a. – the “design now…cost-out later” mentality we discussed earlier). A practical solution to find the right balance is to set a threshold of +/- XX% shift in the market price expectation before you adjust cost targets. This ensure that minor blips are shielded from the development team, while not turning a blind eye to a market that is evolving in front of you.

By establishing these practices and ways of thinking in your program, you have laid the groundwork necessary to move on to the next step: creating cost transparency during the product development phase.