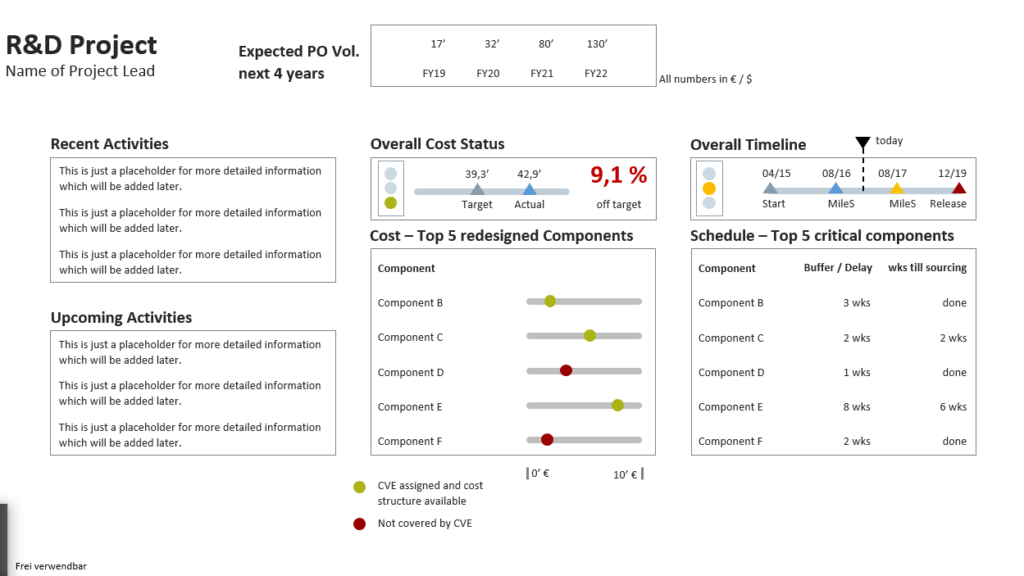

The R&D Project cost and schedule status are the most important KPI’s for a procurement organization. Therefore, it is not surprising that the head of procurement or CPO focus his interest of these two areas. If you are the procurement representative in an R&D project, you should consider this. Many of you have faced already the balancing act to deliver the key message and not getting lost in all the details. I developed a PowerPoint template which addresses the expectations from senior management. This template was already used in many different reviews and is proven best practice.

Continue reading