Supply chain management (SCM) has developed and changed so quickly to meet new business mode and market requirements today. Procurement as one of most important element in SCM is also undergoing significant change, which in sequence impacts its role and responsibility in whole organization. What’s new from procurement to bring bigger impact on business is really an interesting topic worth to understand and explore. This post to explain how procurement acts as a more active role and brings impact in one localization (cost out) project based on author’s experience. In here, Procurement engineer plays the interface/lead role from procurement organization.

Start of the story

Let’s assume we are in below scenario, company product faces very tough competition in China market due to shrinkage of overall market demand and with several strong local and global players in this specific industry area. Below is management decision based on business judgement: Cost out to reach a competitive price level via localization. What’s suitable target cost we need set, How to dig out as more as possible cost out ideas, how to develop cost out road map, what’s investment required for implementation and how long it could be returned back, when could measures could be reflected to real project, and so on. Lots of such questions need to be clearly answered. No doubt procurement could be a key player in driving cost out activities, as we are responsible of more than 50% product cost volume usually, but more important is how we should do?

Target cost setting

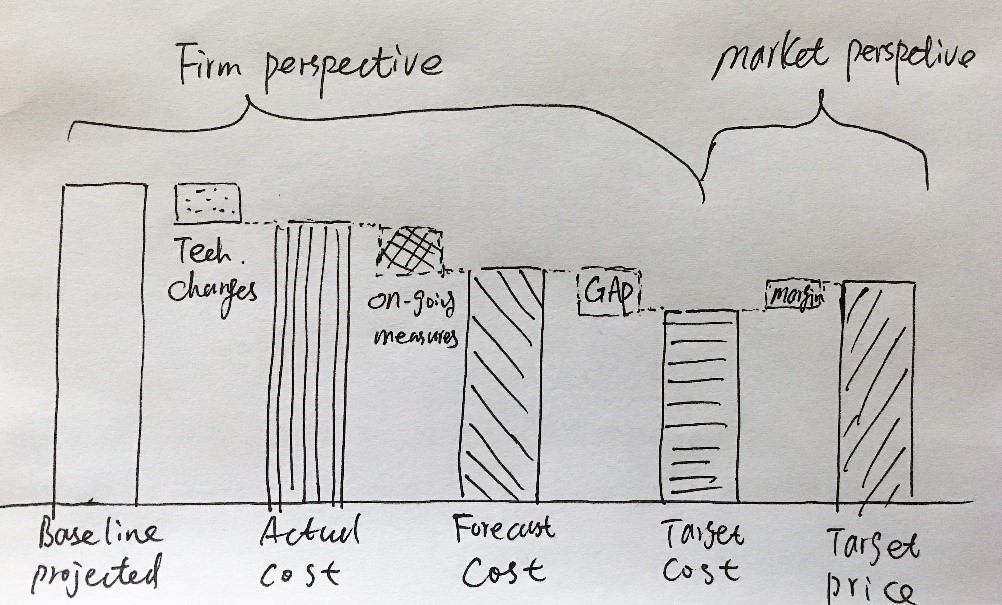

A clear bottom up target cost setting is first thing we need to do immediately at the very beginning of such a cost out project. We are already in half way of success if a clear target cost has been set up and be cascaded to project team. For the target cost, usually this needs a joint effort – procurement engineer (or product line manager) works closely with market/Sales and controlling colleagues, and aims to set up a bottom up cost structure/model based on available cost data and scale down from market target price. Figure 1 demonstrates how to create the target cost and how to manage the cost development. On the most left side of chart is the projected baseline cost (Firm cost perspective), and on the most right side is target price derived from market (Market perspective). In between we bridge all cost data together, like identified cost out opportunities, today’s actual cost, cost out ideas in pipeline, and remaining cost gap existed. Whenever this cost structure/model has been established, transparency has been created which is really helpful to get overview on cost situation and dig into detail cost out opportunities. Of course this also makes report to management easier by a regular sprint cost review manner. Herein we would also expect a big excel table (or other IT tools) lists all detail sub-systems or even components to get very detail level cost information and derives its own target cost which is really beneficial from author’s practice. It’s never overemphasized the crucial of target cost setting process, a clear baseline and detail breakdown cost target creates transparency and a platform to realize an effective cost management, and more important to transfer cost pressure to each team members and fight for jointly.

Cost out idea generation internally and externally

To generate as more as possible cost out ideas plays decisive role, as we can do nothing if no sufficient and high quality ideas are behind. In this session, procurement engineer more plays the role as a moderator to host various session to collect ideas. The most important things are to consider total cost of whole product life cycle, and to take full advantage of external supplier knowledge besides internal knowhow. There are lots of tools available in cost and value engineering family on how to generate cost out ideas effectively, like product convention, sprint, brain storming workshop, supply chain screening, etc.. A proper tool or tools combination should be selected considering complexity of your product.

Some general principles are listed below could be a good guidance in cost out idea generation phase,

- A cross functional “All Star” diverse team should be invited for participant within the organization if possible;

- Utilize design and manufacturing improvement ideas from current or potential external suppliers;

- Benchmark competitor and discuss final customer real needs to understand local market requirements;

- No limitation on ideas and with whole product life cycle in consideration;

- Functional requirement explanation from design engineer before idea generation;

- Track and maintenance all ideas generated without deletion;

As the interface from procurement, herewith author would emphasize again on supplier involvement to contribute cost out activities. As 50-70% of your product cost will be third party sourced for industry business, it is really important to get your supplier on board for our product optimization. Especially today, as development of global division of labor and wider global sourcing activities, more and more manufacture knowledge lays in suppliers end. How to leverage vendors’ expertise knowledge and integrate into localization and design optimization is so critical to success of running such a cost out project.

Implementation road map

Whenever enough cost out ideas have been collected in above session, another question follows is how to turn these ideas into reality and reflect to project with really money back (contribution to net income). This is really the focus from top management and matters. To pull ideas from the moon onto the ground. As Organization always have limited resource and budget, and time window for market entry. To generate a good implementation plan, below aspects are definitely necessary to be considered and mandate to be evaluated.

- What’s the cost benefit, here cost engineer is normally proposed to be involved for commercial estimation in a fast fashion;

- What’s the effort required for implementation, including capex, one time cost, required qualification effort;

- What’s the lead time to complete the measure, as this will a decisive criteria when it could be reflected into real projects and could meet market time window;

- What’s the risk mitigation plan when the measure is fail for risk contingency reservation.

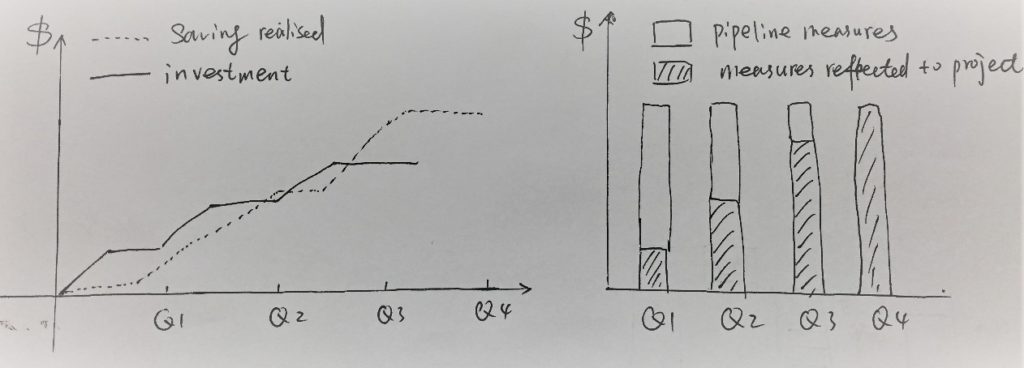

Figure 2 below shows one typical delivery in this session after several rounds detail review of all measures available. For this session, return of investment (RoI) should be kept in mind through all the time. RoI is the main KPI to prioritize the measure implementation plan when the budget is limited.

One additional point project team should also aware is, we can never turn 100% calculated saving into reality without any erosion. As a statistic analysis from previous author’s practice, 30%-40% erosion may happen, so pls don’t too optimistic when report to management for the plan!

Besides, we must not forget to keep close communication with key stakeholders related to the measures, like engineering, manufacture, service, etc. Sometimes the reluctant from stakeholders really becomes a big hurdle. We need to fully understand their concerns and interesting. For example, if the items are related to “make or buyer” decision, we need to align strategy sourcing and internal manufacture network; if the items have patent protected, we need to clarify with legal or impacted parties.

Summary

Today, business expects procurement do more as we own more than 50% product cost volume. Procurement is more a business partner, but not only supporting function to get material in lowest price. As a procurement engineer, early involvement on big cost out project and co-drive the project in a closely cooperation with project manager do bring value and create business impact. A systematic way and process is helpful in today’s more flat and complex organization setup.