Rough cost estimates (RCE) have often a bad reputation. Too inaccurate. Not proven. No basis for decisions. It is true that rough cost estimates have obviously many limitations, but they can help you a lot to be effective and productive.

Continue readingAuthor Archives: Sebastian Waengler

Here me speak: Procurement in Agile Development Programs

I had the pleasure to talk on the last Procurement Summit in Hannover about Procurement and its place in agile Development Projects. Unfortunately it is only available in German ….

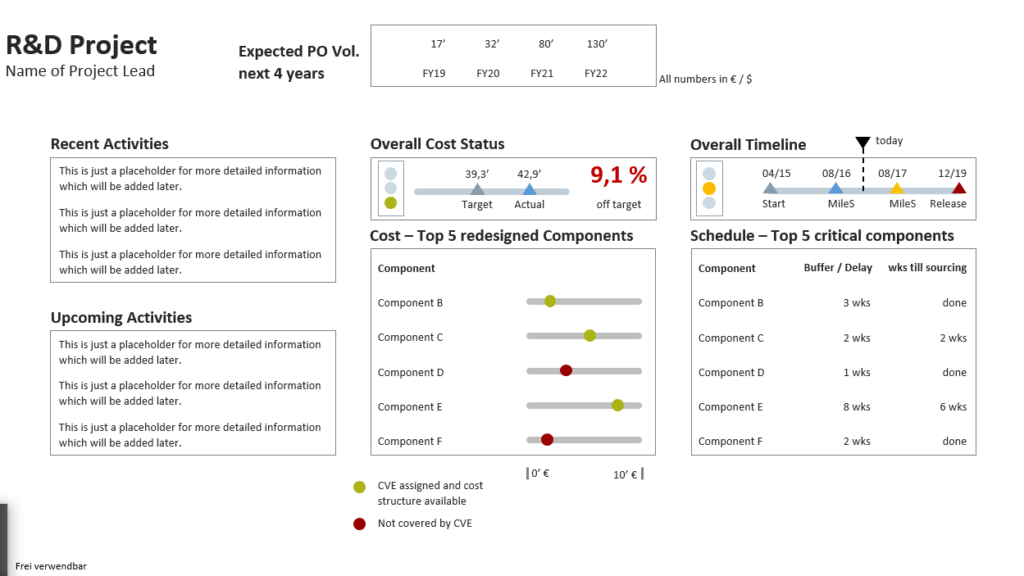

How to report the cost status of a R&D Project

The R&D Project cost and schedule status are the most important KPI’s for a procurement organization. Therefore, it is not surprising that the head of procurement or CPO focus his interest of these two areas. If you are the procurement representative in an R&D project, you should consider this. Many of you have faced already the balancing act to deliver the key message and not getting lost in all the details. I developed a PowerPoint template which addresses the expectations from senior management. This template was already used in many different reviews and is proven best practice.

Continue readingHow to use “Target pricing” and „Target costing” in procurement and what is the difference?

All of you already have experienced the difference between cost and price. Before and after the holiday weekend the fuel price is significantly different while the cost stayed the same. In procurement we deal with supplier prices every day, but is there any value for us to investigate the potential price of our product? The following article will elaborate on the difference of cost and price and how we need to use it in our daily procurement world.

Continue readingWhy Product disassembly is an important lever in the Design to Value process

First of all I have to excuse that there was no new articles posted for the last view months. Corona did also impact us and home schooling, parallel work etc. did impact us as well and there was almost no time for any other activities. Now, as the situation has relaxed, you can expect again some insights in modern procurement engineering and cost / value engineering approaches.

Today I want to share some thoughts why „product disassembly“ is an important lever in the design to value process and how you can use it to generate a competitive advantage. So, why should you do product disassembly?

Continue readingThe Essentials of Procurement Engineering

We’re now working on procurement-engineering.com more than one year. Looking back and reviewing everything shows that we really have put together a nice overview of the most important things in Procurement Engineering. You will not find a better crisp overview. See and find out …

Cost and Value Engineering

Procurement Engineeing is well connected with Cost and Value Engineering. Many Posts deal with the interface between CVE and PE:

Cost Engineer vs. Procurement Engineer Link

Continue readingHow to lever “Design to Customer Value” in your daily work

In one of my previous articles I introduced you to different methods or levers to maximize the outcome of your work. We call it “Design to Value”. The article on “Design to Cost” was the first one. I continue you now with an article on “Design for Customer Value”.

It is a little bit confusing that “Design to Customer Value” is a sub category of “Design to Value”, but you really have to highlight here the “Customer”. Essentially it is about to understand the real needs of the customer and how the product can generate value for our customer.

Continue readingEssential methods for „Design to Value” (DtV) in Procurement and Cost & Value Engineering – Design to Cost

We talk about “Design to Value” and “Design to Cost” how to run related projects, but before we start to talk about the methods how to lever “Design to Value” (DtV) we have to understand what “Design to Value” means. Basically, DtV means a design approach for new products or systems where the maximization of the value for the customer is the determinant target. In a broader sense, DtV extends the Design to Cost approach by further methods and approaches. Every design feature or design concept is therefore measured whether or how much value it creates for the customer or not.

Continue readingEngineering as key for global value sourcing (GVS) and how to estimate the GVS potential

Globalization is one of the „current“ mega trends. This means for you as a procurement guy that one of the biggest levers for cost reduction is „global value sourcing“, which does not mean anything else than that you select the most competitive supplier from all over the world and you don’t limit yourself to a certain region. In the following article we will deal with the questions how to identify the right components and services for global value sourcing and how engineering can help you in procurement to get the most out of global value sourcing.

Continue readingFirst things to do after setting up a Procurement Engineering organization

You have set up a new Procurement Engineering organization or you have identified some smart and engaged engineers / buyers and they will work in the future as Procurement Engineers. What are the first things you need to to in order to bring the organization up to speed and to create value. We have put together the most relevant things to do in the first 100 days.

Continue reading