Globalization is one of the „current“ mega trends. This means for you as a procurement guy that one of the biggest levers for cost reduction is „global value sourcing“, which does not mean anything else than that you select the most competitive supplier from all over the world and you don’t limit yourself to a certain region. In the following article we will deal with the questions how to identify the right components and services for global value sourcing and how engineering can help you in procurement to get the most out of global value sourcing.

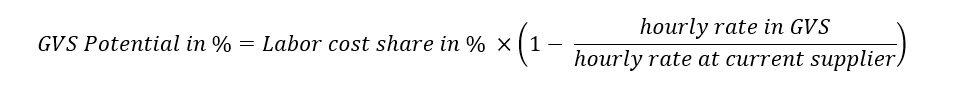

Imagine you have just started as a new commodity manager; the first thing you will do that you develop for yourself an overview of the current procurement strategy. You should have an overview for every component or system where it is sourced, for how long prices, volumes are covered by contracts, and where you have the need to react as new designed components will be added to your portfolio or existing contracts expire. Let’s pick one component where you have the freedom or the need to search for a new supplier. Regarding the aspect of global value sourcing you should answer first the question whether there is a potential for that component to go to a low-cost country. Will you generate value for the company to do so? How do you answer this question? If we talk about a low-cost country, we generally mean that the labor costs are low in that country. Therefore, global value sourcing gets with in increasing labor cost share in the component more attractive. You first Action Item is to develop a first cost breakdown of the component and calculate the labor cost share. Based on that the following equation gives an idea about the potential you can generate by moving to a low-cost country:

Of course, you will neglect with that easy equation most likely GVS country advantages in energy or facility costs, but normally these cost drivers are minor compared to the labor costs and the proposed equation is reasonable. The experience shows that the cost-out potential should be at least 15 % to ensure that the end there is a cost benefit if you include the cost of identifying the new vendor, communication and qualification efforts. The 15 % are only based on experience and you should make your decision based on a more detailed review of the expected costs of developing a new vendor in a GVS country.

Once you are convinced that there is a potential to source this component from a low-cost country and you have contacted the first vendors you will be most likely disappointed that the quotes coming in by far higher than what you have calculated. One reason could be that the suppliers want to boost their margin, and everything is tactics, but there could be also another reason …. and as I mentioned in the headline engineering could be the key to leverage the full potential. The easy equation where we calculated the potential has a very big shortcoming. It assumes that the methods and processes are at the high-cost country supplier and the low-cost country supplier are identical, but in many cases, they are dramatically different. To really fully leverage the potential, you must discuss and review with the supplier the manufacturing plan and processes and you need to understand which feature of the design is driving the efforts at the potential vendor. In many cases there might be even features which makes the design not manufacturable at all. Thinking this through it is obvious that you need to consider the GVS suppliers already in the concept and the design phase, so that the manufacturing limits can be considered. Hence, it is of major importance that you work early on with engineering and make them aware that cost-out in design does not mean an easy to manufacture design for a high sophisticated vendor in a high cost country, but an easy to manufacture and robust design for low cost countries. Design to cost means design for global value sourcing. If you work to transfer designs which require a high vendor skill set and high end manufacturing technologies you will fail to generate considerable value add through global value sourcing. The real key is that you consult engineering in the concept phase regarding you supply chain strategy and which kind of manufacturing methods they have access to, and which manufacturing technologies would design a GVS vendor out. The following check-list summarizes what you need to do to get the most out of GVS:

- Assess your current portfolio where labor cost is a major contributor to the overall cost of the component.

- Determine whether the identified components require high end manufacturing skills or not.

- Take the low-end components and directly transfer them to GVS suppliers.

- Develop with engineering a roadmap to assess the design concepts of components with tough manufacturing requirements. Depending on the cost-out potential this could be done in a separate design to cost project or in the course of technical driven design update.

- Ensure that the new designed components can be sourced in GVS countries through Early Supplier Involvement. Procurement Engineering needs to orchestrate here the manufacturing input from the GVS supplier and make sure that the voice of manufacturing is heard from Engineering.

The last thing to mentioned is that Procurement needs to have a very clear understanding early on how the future supply chain look like. If Procurement waits until the design is fixed there is only limited chance that most competitive GVS supplier can manufacture the components / systems.

Key takeaway: The main task for Procurement Engineering is to ensure that new developed designs can be manufactured by GVS suppliers. If Procurement does only play a passive role during design development and tries to roll out GVS sourcing with mature designs, it will fail. Well integrated Procurement Engineering means GVS sourcing by intend, not by chance.