Once in a live most of the car owners need to buy wheels for his car. The question is: Which price is reasonable for the product? Which kind of wheels to choose? In this article you will find answers on that question. Additionally, you get an overview about a cost structure of an aluminum casting product using bottom up cost calculation method. We think it’s a perfect example to show how cost value engineering contributes to the company’s success and could also help you in your private life.

Product selection and rough property comparison

I did it recently. I bought a car and needed new wheels. Since there is an amazing price range, I asked myself the question why.

It is not all about the material. Sure, we can differentiate between steel and aluminum. Aluminum is known to be a light metal. But are all aluminum wheels buy law lighter than simple steel wheels? Not at all. Steel wheels are made by forging process which gives them thin geometry with high mechanical properties coming from steel and the process. Aluminum wheels can be produced in more than one method. They can be forged or casted. Forged aluminum ones can be lighter than steel ones but casted most likely not. Just on point is a fact – aluminum wheels are more attractive.

Helping you by selecting the best wheels for your purpose just considering technical data is not so easy as you can see. Therefore, I stop here and just focus on good design for lowest cost which is casted aluminum wheels.

Working in the environment of several different industries for castings I had the chance to see also aluminum wheel casting houses. Based on that I picked one basic wheel for a small German car for my analysis – Volkswagen Polo. (see Figure 1)

How to setup a bottom up cost calculation

In order to setup a proper calculation some basic figures are needed. A small selection you can already see in Figure 1.

Next step is material selection, process definition and process map preparation. Please be aware that there are so many different wheels out there with so many different features. Especially surface treatments can make a big difference in costs. I selected a basic wheel just as an example.

For my example I assumed a gravity die casting process with all post casting process steps in East China – Zhejiang province. As per my example you can see about 17 main process steps which are necessary to produce such kind of wheel. Please ignore the cost in Figure 2 since these costs are without any material & overhead figures and will come later in more detail.

Cost break down for aluminium casting weel

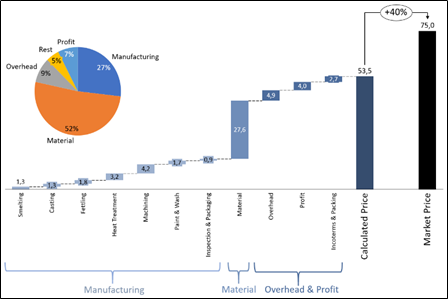

After inputting all the data (manufacturing steps, SG&A, Profit and general payment terms) you will get a price with a cost break down. (see Figure 3)

Sure, this is unreasonable since sales is needed to present the parts in other country markets. But if the 40% mark-up is fair – this is up to you.

Looking into the cost break down you can see the huge cost impact of the material (>50%). Please consider that the aluminum price is centrally traded in Europe, US and China. Pending on the market and the point in time the prices are very volatile.

Other than bore you with further details of the calculation I leave it as is. Now you can dream of 40% lower prices on your new shiny aluminum wheels.

Key message is: You could save 40% if you would be able to get the parts directly from the manufacturer. And a cost value engineer with you bottom up cost calculation helps you to realize that.