In the course of my different positions within procurement pretty often people asked what is actually the difference between a Procurement Engineer and a Cost (Value) Engineer. Why Value in brackets? Cost Engineer is more common, but in some organizations the position of a Cost Engineer is also designated as Cost Value Engineer. Where does the confusion come from?

- Cost Value Engineers (CVE’s) and Procurement Engineers (PE’s) are both “hosted” in the procurement organization.

- Both positions demand a sensibility regarding cost-out and are regarded as the cost-out drivers.

- In most cases they work together with Engineering in development projects.

So why are there two different positions, if the role is so similar?

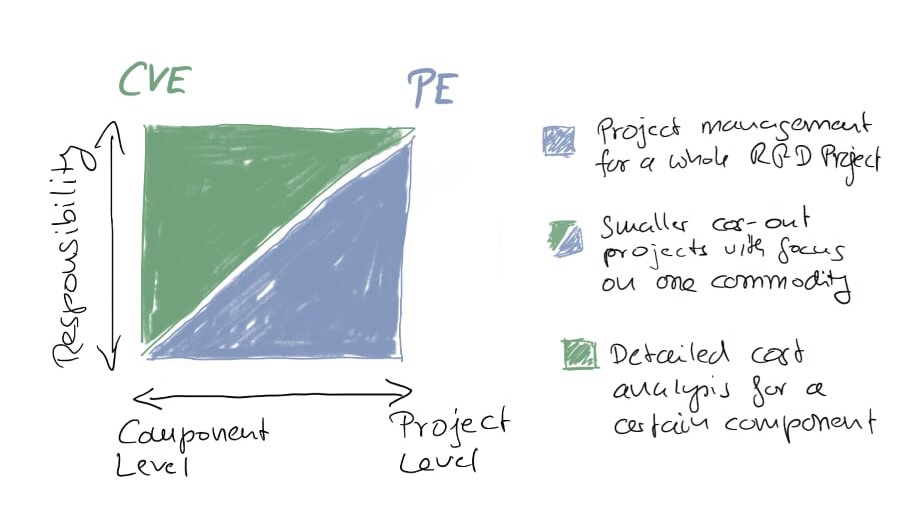

Procurement Engineers are working on the project management level. They do ensure that the Procurement organization is involved at all in the development project. They ensure that the different activities are staffed with the right people from procurement and manages the overall procurement activities within the project. His or her main interface are the Engineering managers in the project. The PE does normally not have very specific knowledge about certain manufacturing methods or is very skilled in to doing in deep cost analysis. The PE requires support from real specialists – the CVE’s.

Cost Value Engineers are specialist for a certain manufacturing method as e.g. casting, welding or assembled systems (electric drives, gearboxes etc.). They do normally have experience as a manufacturing engineer or worked in procurement positions where they did gain experience on certain manufacturing methods. With that know-how the CVE is able to develop independently from input from the vendors a should cost model what a certain design concept should cost in vendor based in India, Germany, or Northern America.

Visualization of Procurement Engineering and Cost Value Engineering responsibilities

In contrast to the CVE the PE does not do any cost analysis by him- or herself, but he ensures that these cost analysis (bottom-up calculations, shadow-calculations, benchmarking, scaling …) is available where necessary and useful for the project. He also ensures the the required CVE resources are available and enabled (access to the necessary information).

There are certain development projects where the parallel use of PE’s and CVE’s is not necessary. An example might a re-design of a component where only a specific manufacturing know-how is necessary. In these cases it depends on the individual skill set of the PE / CVE to decide who might the the right one to support it.

Key Take Away: Cost Value Engineers are specialist for certain manufacturing or assembly methods providing in deep cost transparency while the procurement engineers acts more as a procurement project manager.

If you would add “R&D-” to “Project level” and “add “Cost” to “Project management for a …” partly ok, dependent what you mean with the term “component”. Cost and value engineers (CVE) usually taking a whole system (could be a product or part of product, a service, a customer project) under “cost and value” consideration. For that CVEs do have a complete tool box “CVE methods” on hand. Detailed cost analysis is one of around 20 of such methods.